The Challenge

Training technicians on Heat Exchanger is crucial for industrial and engineering field of oil and gas, petrochemical , which encounters several challenges as outlined below.

•Complex designs make training challenging.

•Hard to understand heat transfer without hands-on experience.

•Troubleshooting issues requires real equipment.

•Limited models and resources hinder training.

•Safety protocols need simulation tools.

•

These challenges make heat exchanger training both resource-intensive and complex

The Solution

The project was developed to help users better understand the functionality of a heat exchanger. The process design and development began with creating a detailed 3D CAD model of the heat exchanger in Blender software.

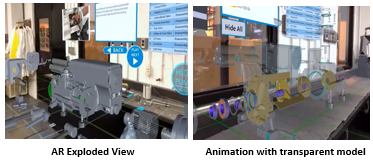

The finalized model was imported into PTC Creo Illustrate to create exploded views and animations of the heat exchanger’s components. These animations were then used in Vuforia Studio to develop an interactive AR experience.

The AR experience featured a 3D panel for component labeling, reference images for visual guidance, and visibility controls to toggle individual parts, enabling users to explore and learn about the heat exchanger’s assembly and functionality.

The Results

•Reduces training costs by eliminating physical setups and in-person trainers.

•Speeds up learning, enabling faster employee onboarding.

•Minimizes errors in assembly and maintenance, lowering downtime and costs.

•Supports on-demand, remote training for flexibility and cost savings.

•Enhances ROI through time, resource savings, and improved productivity.